SlimLine® Resistance Welders

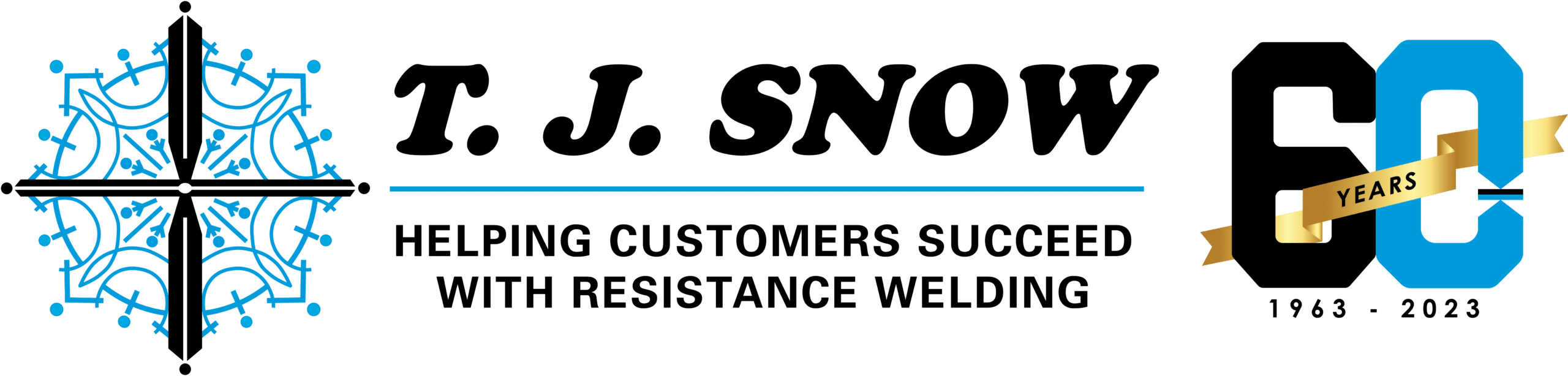

Pedestal-Type Spot Welders, Projection Welders,

Multi-Gun Spot Welders, and Seam Welders

The durable, compact design of T. J. Snow’s SlimLine Resistance Welders makes for a cost-effective and efficient resistance welding solution. All standard SlimLine components are stocked at our Chattanooga location, so we can assemble on to your specifications in record time. SlimLine Welders are available in Pedestal-Type Spot Welders, Projection Welders, Multi-Gun Spot Welders, and Seam Welders.

SlimLine Standard Specs

- KVA: 30-170 KVA AC and MFDC

- Throat Depth: 18″ to 36″

- Voltage: 220V, 440V, 575V

- Single Phase and 3 Phase (with MFDC)

- Air Cylinder Type: Standard Dual Acting, Air Over Oil, Ram Type, and Other Options

- Air Cylinder Stroke: Up to 6″

- Machine Initiation: Foot Switch, Palm Buttons, Automatic, PLC

Standard Features & Options

- Rigid, heavy-duty frame

- Precision-machined mounting surfaces

- Easy access for maintenance & tooling changes

- Fork lift pockets for safe & easy handling

- Fixture-type transformer, heavy-duty, water-cooled

- Brace for Horn style lower arm

- Easily adjustable electrode gap

- Shrouded foot switch

- Choice of welder controls

- Available in 220, 440 & 575 voltages

Advantages of SlimLine Spot Welders

- Easy to Customize

- Add Welding Guns

- Widen Lower Platen

- Install Special Tooling

- Durable compact design

- Easy access for simplified maintenance

- Quick changeover

Recommended Upgrades

- Closed-loop recirculating water chiller

- Lockable electrical disconnect built into control cabinet

- Dual palm button installation

Additional Configurations

- Multi-gun upper & lower platens

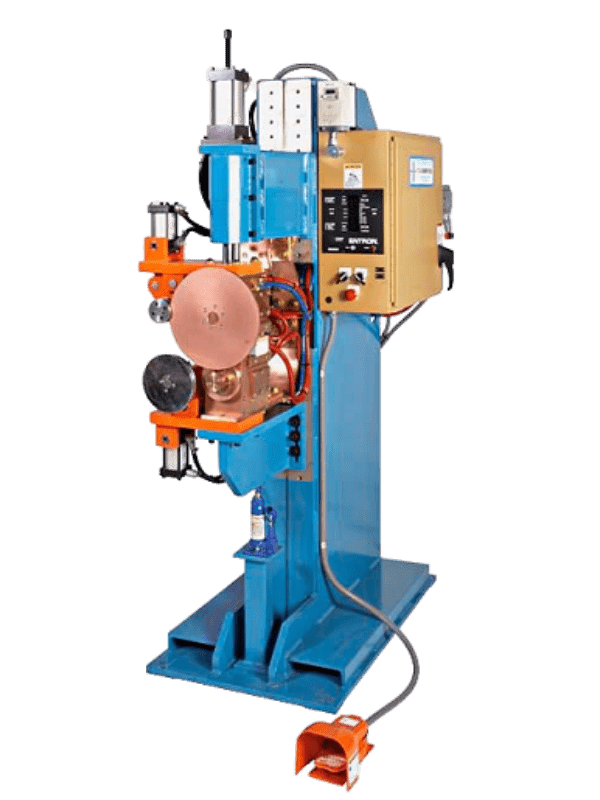

- SlimLines are available as Seam Welders

- Opposed or angled guns

SlimLine Seam Welder

Premium Options

- MFDC Power Supply & Control

- Consistent, controllable DC wave form

- Shorter weld times

- Improved weld appearance

- Longer electrode life

- Reduced power consumption

- Electric Servo-Driven Force Delivery System

- No expensive & dirty compressed air

- Weld force generated almost instantly

- Slow approach to minimize electrode wear

- Consistent control of variables

- Set-down & stack-up verification

- Data logging feature with Excel export function

- Guided Ram

- Allows use of platen-mounted upper arm & standard electrode holders

- Unitrol Soft Touch

- A unique sensor function integrated into the weld control that minimizes operator finger or hand entrapment accidents, by keeping the electrode pinch-point force low until it is safe to apply full welding force

| Throat Depth | Max Available Weld Force (lbs.) **(Std. Cylinder @ 80 psi) | Max. Short Circuit (Tip to Tip) Amps at % Duty Cycle* | Horn Diameter | Maximum Stroke | Holder Diameter | Footprint | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Single Phase at 50% | Three Phase MFDC at 5% | L | W | H | ||||||||

| 85 KVA | 120 KVA | 135 KVA / 600A Inverter | 170 KVA / 1000A Inverter |

|||||||||

| Horn Style | 18" | 1,344 | 18,900 | 24,000 | 22,000 | 2.75" | 3-6" | 1.25" | 52" | 36" | 78" | |

| 24" | 1,344 | 17,500 | 22,500 | 38,000 6 Cycles | 58" | |||||||

| 30" | 1,344 | 16,300 | 20,600 | 35,000 7-12 Cycles | 64" | |||||||

| 36" | 1,344 | 15,100 | 19,100 | 30,000 13-24 Cycles | 70" | |||||||

| Platen Style | 18" | 1,344 | 18,900 | 24,000 | N/A | 3-6" | Platen Style | 52" | 36" | 78" | ||

| 24" | 1,344 | 17,500 | 22,500 | 58" | ||||||||

| 30" | 1,344 | 16,300 | 20,600 | 64" | ||||||||

| 36" | 1,344 | 15,100 | 19,100 | 70" | ||||||||

Ready to Discuss Your Resistance Welding Solution?