Air Cooled Jumper Cables

T. J. Snow stocks a wide selection of air and water cooled cables as well as shunts for your resistance welder. If you have questions, please contact our Customer Service Team. To order an air cooled jumper cable, you will need to know several specifications for that cable. The following will walk you through that process.

Step One

Select Styles of Terminal Ends

F

R

L

LO

V

VO

Step Two

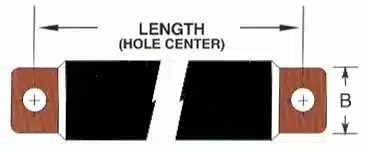

Taking Measurements

- Length of the Cable =L

- Terminal Face Width = B

- To get L, measure from the center of one set of mounting holes to the center of the second set

- The secondary measurement, B, is the face width

The terminal thickness is dependent on the terminal face width, and the gauge of the cable, as outlined in the table on the right.

| MCM | 1.250" Wide | 1.375" Wide | 1.500" Wide |

|---|---|---|---|

| 400 | 0.405" | 0.370" | N/A |

| 500 | 0.510" | 0.465" | 0.425" |

| 600 | 0.540" | 0.490" | 0.450" |

| 750 | 0.650" | 0.590" | 0.545" |

| 1000 | 0.825" | 0.750" | 0.690" |

| 1200 | 0.965" | 0.880" | 0.805" |

| 1500 | 1.165" | 1.060" | 0.975" |

| 2000 | N/A | 1.575" | 1.440" |

NOTE: The standard terminal width is 1.250″. If a 1.375″ or 1.500″ wide terminal is desired, please be sure to specify this. If you are unsure of what MCM your application requires, you can size the correct cable yourself here.

Step Three

More Cable Options

Isolated Conductor (IC)

Cables with isolated, individually wrapped conductors increase cable life by preventing common failure points:

- Eliminated Frictional wear between adjacent copper ropes by encasing them in rubber tube.

- Reduces the number of friction points for wear between strands from 36 to 9, in the rope cross section.

- Reduced strand failure at the rear terminal by adding a Stabilizer flare.

- Increased flexibility due to the fact that a standard lapped cover is not required.

Note: Thermal tests have indicated that the operating temperatures of this style is virtually identical to that of standard jumper using a lapped cover.

Stabilizer Collar (SC)

Increased strand life at the cable terminal is the advantage of a stabilizing collar. It slightly increases the minimum flex radius for the jumper, reducing over flexing.

Extra Flexible (XF)

36 AWG copper rope stranding and an extra flexible protective cover are used to create an extra flexible jumper. The result is a jumper that is over twice that of a regular jumper. This makes it ideal for robotic applications and where limited space makes standard cables a hard fit.

The DJ-XF is available in 750, 1000, and 1200 MCM. Other options include a perforated cover or a special Hypalon high temperature cover, able to withstand 300°F to -30°F.

Step Four

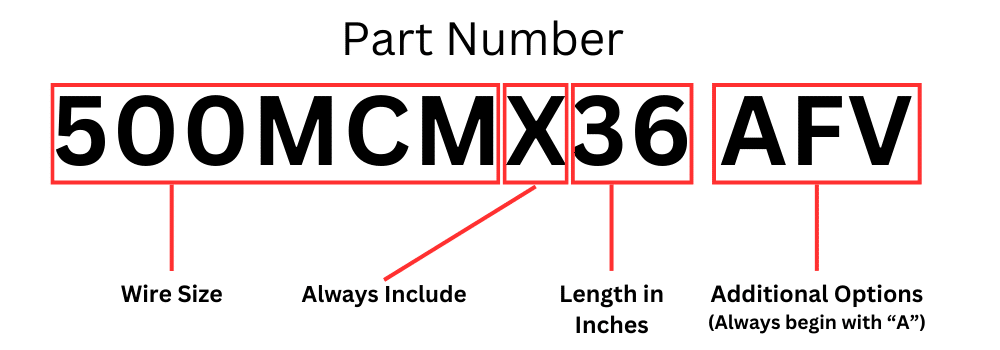

Calculating the Part Number

Ready to Order?

Air Cooled Jumper Sizing

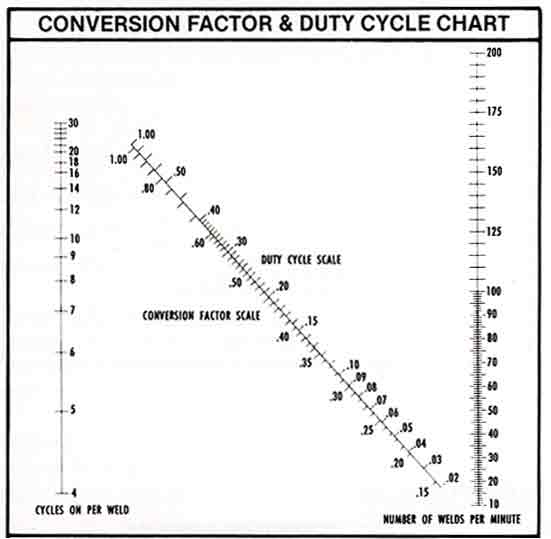

Use the following method to determine what size cable should be used for your application. First you use the Conversion Factor chart to determine your “Continuous Duty Current”; then you read the correct size cable off the second chart. An example is worked out below.

Step 1: Lay one side of a straight edge across the graph at the six cycles of current “one time” point (the left hand vertical scale of the conversion factor chart).

Step 2: Pivot the other end of the straight edge across to line up with the “60 welds per minute” on the far right vertical scale.

Step 3: At the intersection of your straight edge with the diagonal conversion factor scale line, you should be able to read a conversion factor of .32 off the lower 1/2 of the line.

Step 4: Multiply the required current (10,000 amps) by the conversion factor (.32) to get the “continuous duty current” of 3,200 amps. Now proceed to the Air Cooled Jumper Selection Chart to read complete the selection.

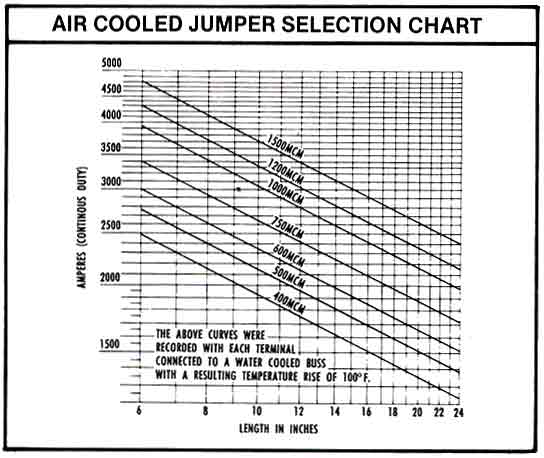

Step 5: Line up your straight edge on the 3200 continuous duty amp mark, and find the intersection with your desired length line (from below).

Step 6: Any cable whose line is above this point may be safely used, since the load it would carry will be within its thermal capacity. In this example a 1200 MCM cable can be used and stay within design tolerances.

Example Data:

6 cycles of current “on time” per weld

60 welds per minute

10,000 amps per weld

10 inch cable Length

Installation Guidelines

How to install air cooled cables

Good Working shapes for Air Cooled Cables

Air cooled jumpers should be installed in such a manner that the mechanical stresses at the terminals will be reduced to a minimum. This may be accomplished by installing the jumper with a little slack, which will allow the jumper to flex freely.

Bend radii should not be sharp, and should be distributed throughout as much of the jumper as possible, in order to distribute the frictional wear over the greatest possible area. See the below charts for suggested minimum bend radii.

Recommended Minimum Bend Radii:

500 MCM and Below: 2″

600 MCM – 1500 MCM: 3″

Minimum Distance from the end of the hose to the point where the bend radii should start is:

350 MCM – 600 MCM: 2″

750 MCM: 2-1/2″

1000 MCM: 3″

1200 MCM: 3-1/2″

1500 MCM: 4″

More Specifications

D.C. Resistance of Single Conductor Air Cooled

(and Water Cooled) Cables

| MCM | D.C. Resistance |

|---|---|

| (Ohms per foot at 70°C) | |

| 350 | .0000376 |

| 400 | .0000322 |

| 500 | .0000263 |

| 600 | .0000217 |

| 750 | .0000172 |

| 1000 | .0000130 |

| 1200 | .0000110 |

| 1500 | .0000088 |

| 2000 | .0000066 |